technology

NEXT level roti

technology

Rotimatic NEXT uses cutting edge Vision AI and Kneading Intelligence to simplify and automate the traditional art of Indian roti-making for modern kitchens.Trained by making over 200M+ rotis in 100,000 homes across 58 countries, Rotimatic NEXT is designed to give you thinner, softer rotis every time and is simple enough to be operated by any member of your family.

*Subject to eligibility check and approval. Estimated payment amount excludes local taxes.

Payment conversion charge may apply as per the service provider.

Versatility

Rotimatic NEXT empowers you to create a variety of flatbreads using multiple flours, including gluten-free options, with ease.

Modern, Sleek Design

Rotimatic NEXT features a sleek, modern design that complements your kitchen effortlessly.

Whisper Quiet Operation

Designed for quieter operation, it ensures a seamless and peaceful cooking experience.

Simple, single-tap cooking

NEXT level superpowers

for your kitchen

Cutting-edge technology makes Rotimatic NEXT the perfect roti maker for any modern home

Multi-flour compatibility

An incredibly sophisticated engineering marvel, your Rotimatic NEXT is designed to handle multiple flours. From the regular wheat flour to gluten-free flours like almond flour, sorghum flour, brown rice flour and more. Allowing users to explore and experiment with a wide range of flatbreads; puri, pizza, millet rotis, paratha and many more. With absolute ease.

Fully automatic operation

The complex art of making a roti from mixing and kneading dough to cooking a perfect roti, Rotimatic NEXT does it with the simple press of a button, in just 90 seconds. Easy enough to be used by any member of the family. Even your little one.

Whisper-quiet operation

Built-in noise reduction ensures that while an incredibly complex system of motors, sensors, and other moving parts works in perfect tandem inside, you barely hear a sound.

Enhanced Consistency

With Vision AI and enhanced Kneading intelligence, Rotimatic NEXT consistently delivers your preferred taste. Every time.

Kneading Intelligence™

An incredibly sophisticated system of sensors and motors ensures perfect dough consistency. It monitors factors like weight, moisture, type and proportion of flour in real-time. Tactile sensors replicate human touch for perfect dough texture. Trained by making over 250 million rotis, the system is designed to improve with usage.

Real-time Dough Monitoring and Adjustment

The Kneading Brain monitors dough-making in real-time, adjusting weight, moisture, and ingredient ratios to suit the flatbread type. It ensures consistent results across various doughs, adapting to different ingredient properties such as flour types.

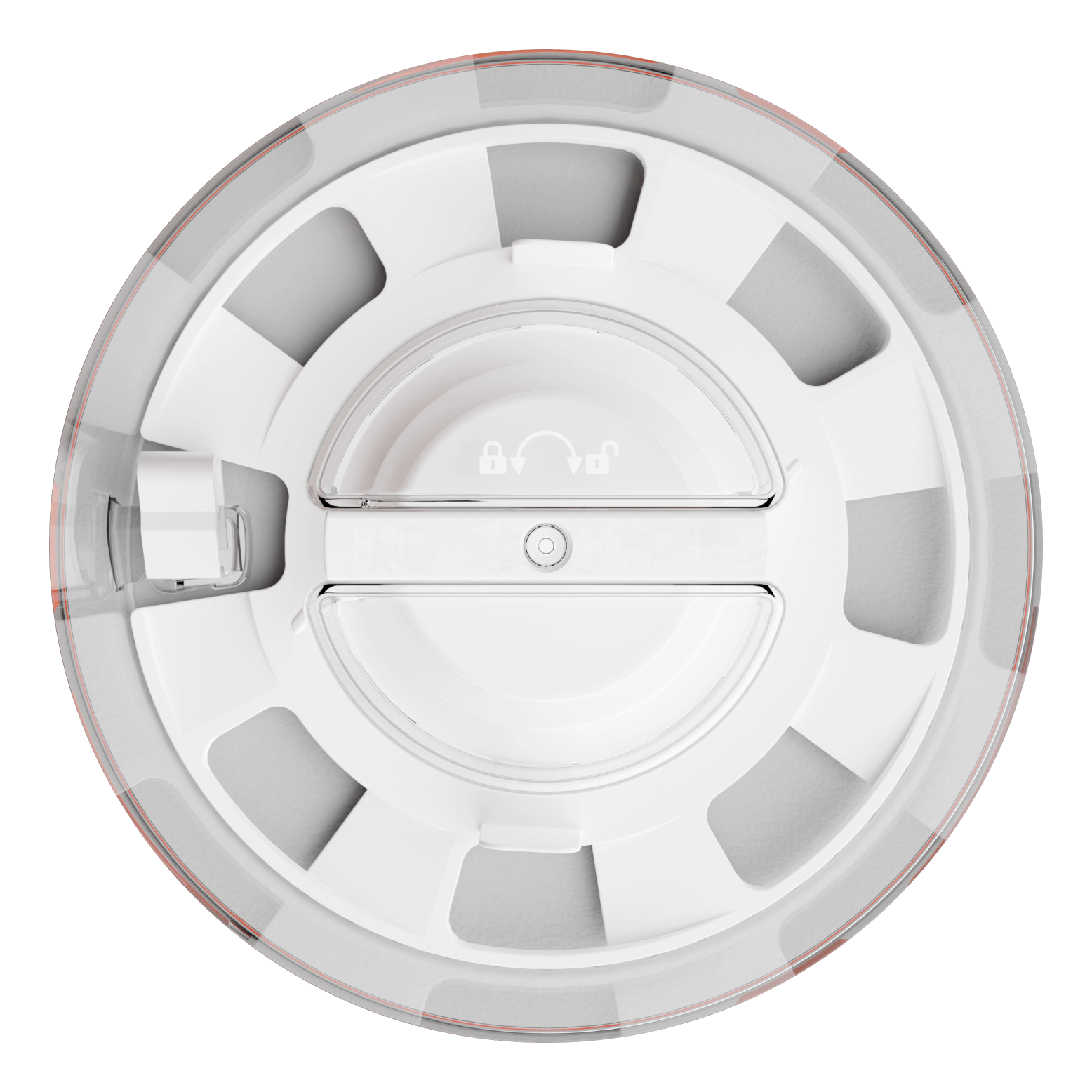

Tactile Sensor System

Advanced tactile sensors within the machine simulate human touch, assessing dough hardness and texture in real time. When necessary, the system adjusts its kneading technique to optimize results. This Kneading intelligence technology consistently produces high-quality flatbread dough, adaptable to various recipes, by mimicking human kneading methods.

Learning Algorithm Based on 250 Million Rotis

The Kneading Brain has learned from producing over 250 million rotis, continuously improving its kneading techniques and enhancing dough quality with each use. As it collects data, the machine becomes more intuitive, refining its processes and consistently preparing higher-quality, more adaptable dough over time.

Vision AI

An advanced visual processing system ensures the dough is shaped and cooked to perfection, giving you a fully puffed roti every time. A high-resolution camera monitors dough and roti quality in real-time. The system analyzes texture, size, and shape of both to make necessary adjustments.

Monitoring Dough Quality

A high-resolution camera captures real-time dough footage, analyzing texture, size, and shape to ensure quality. Vision AI guarantees perfect flatbread texture and appearance every time.

Sensor-Based Adjustments During Cooking

The Rotimatic's hot press uses sensors to monitor dough surface, heat distribution, and bubble formation. Vision Al technology adjusts pressure and heat in real-time for even puffing and perfect cooking. These continuous adjustments guarantee consistently high-quality thinner and softer rotis.

1-2-3, make your roti.

Power on and add ingredients

Start the machine, add flour, water, and oil to the designated compartments.

Choose your settings

Select your preferred flatbread type, adjust settings for thickness, roast level, and oil. You can manage these settings via the LCD screen on the machine or via the Rotimatic app.

Done in 90 seconds

Your Rotimatic NEXT will automatically knead and flatten the dough, and roast it to perfection with the texture, puff, and roast level chosen by you.

Enjoy fresh Roti

After about 90 seconds, the fresh roti is ready and automatically dispensed from the machine, ready to enjoy.

Technical Specifications

Size & Weight

Width

Height

Depth

Weight

Performance

Voltage

Power

Frequency

Noise Level

Kneading

Compare your Rotimatic

Features

AI Enhancement

Noise Level

Roti Quality

Recipes

Connectivity

Design

Technical Specifications

Dimensions

Weight

Voltage

Power Rating

Frequency

Out of the box technology

Rotimatic Machine

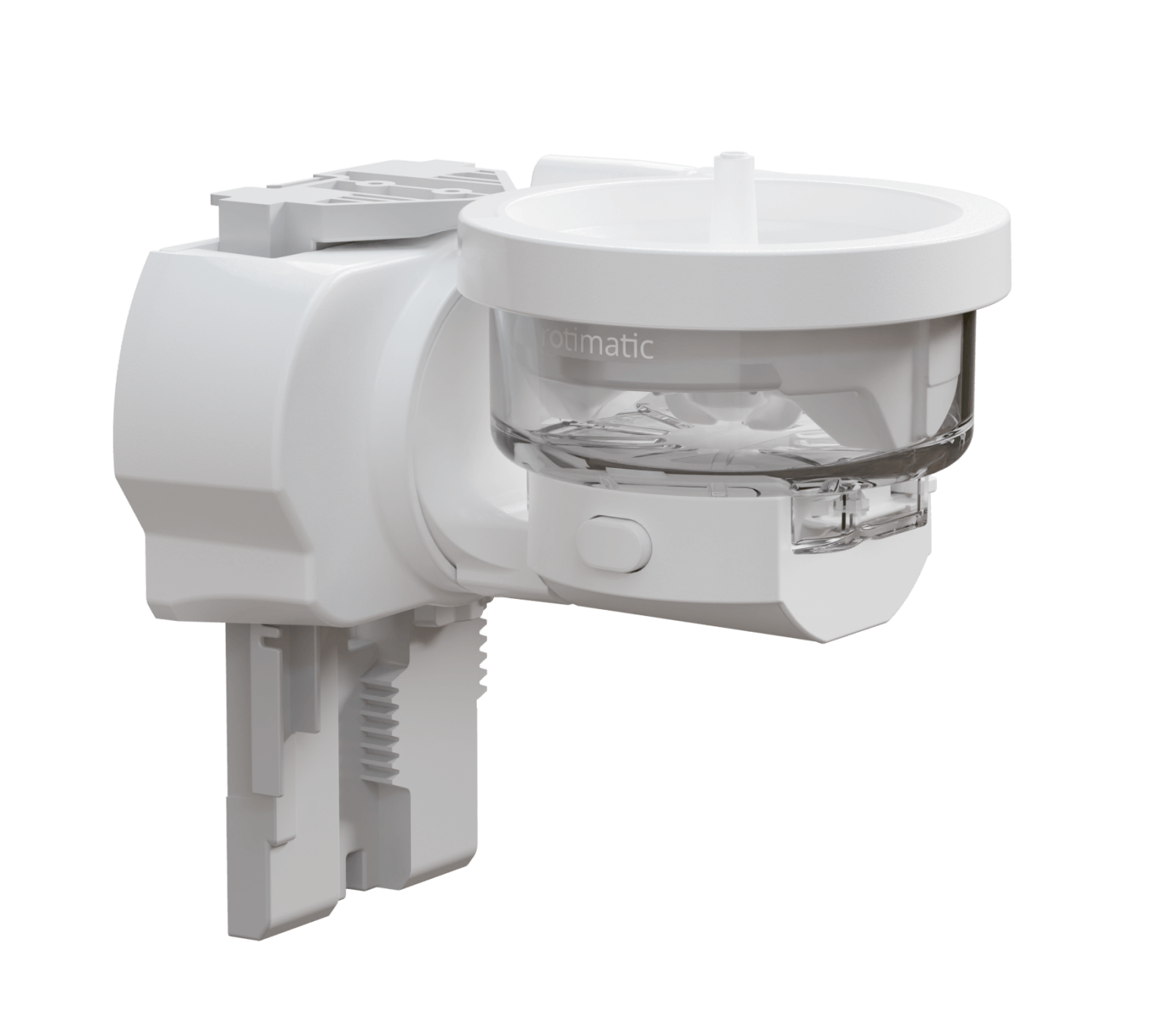

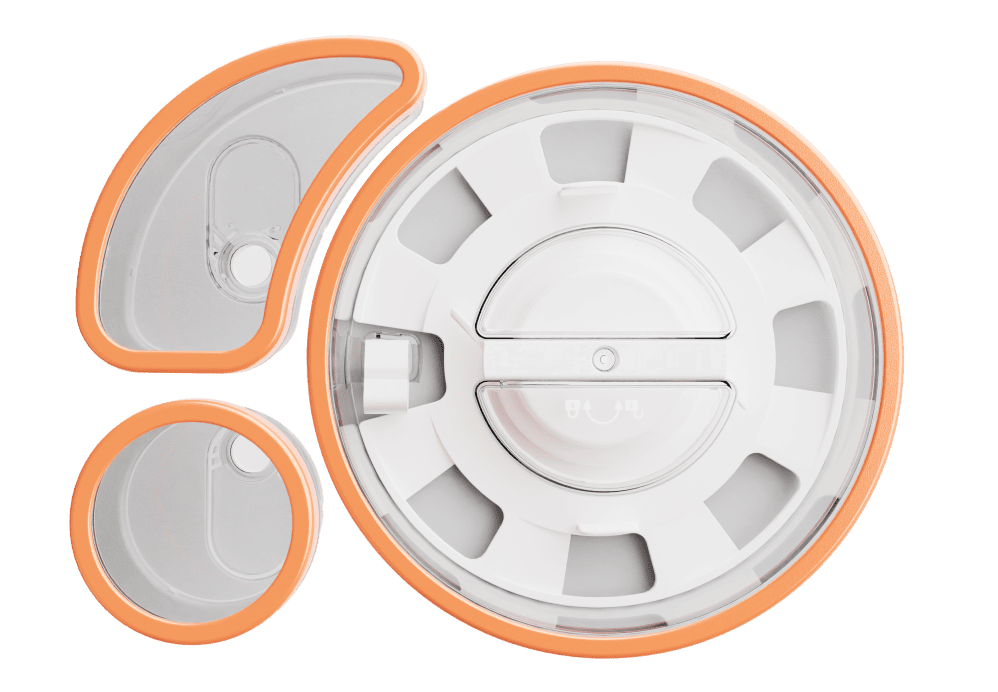

Container Set

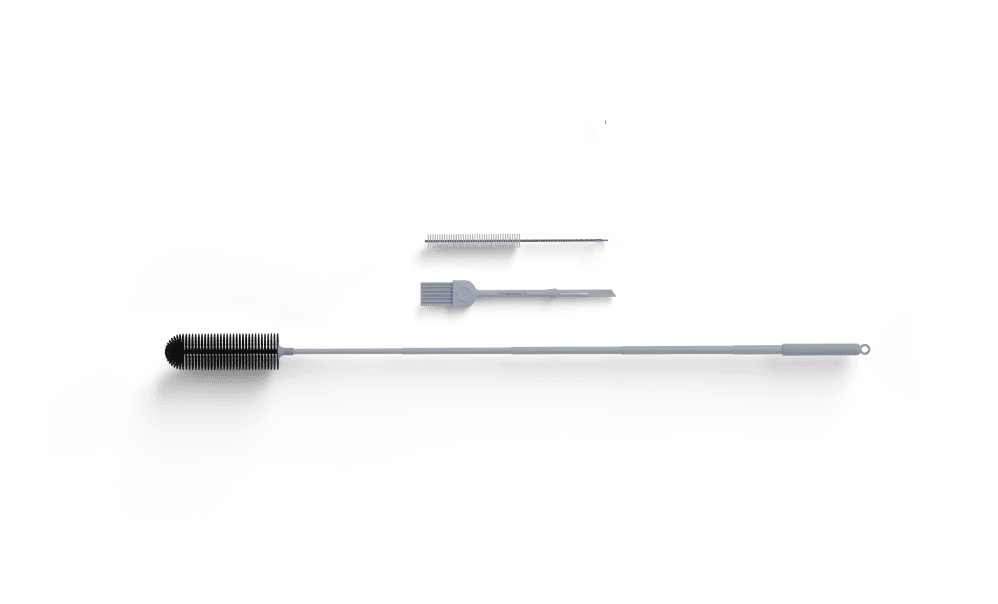

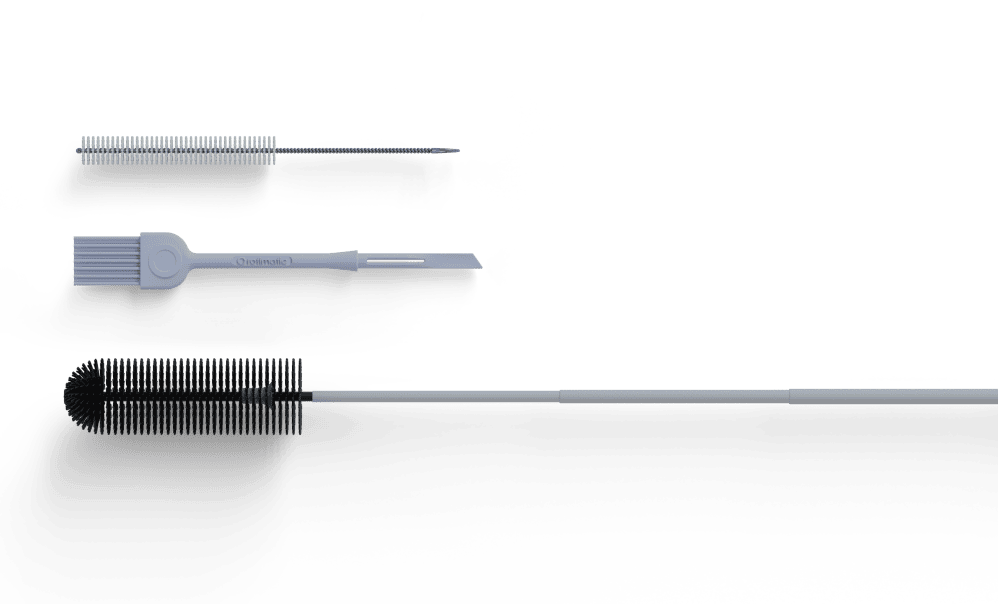

Cleaning Kit

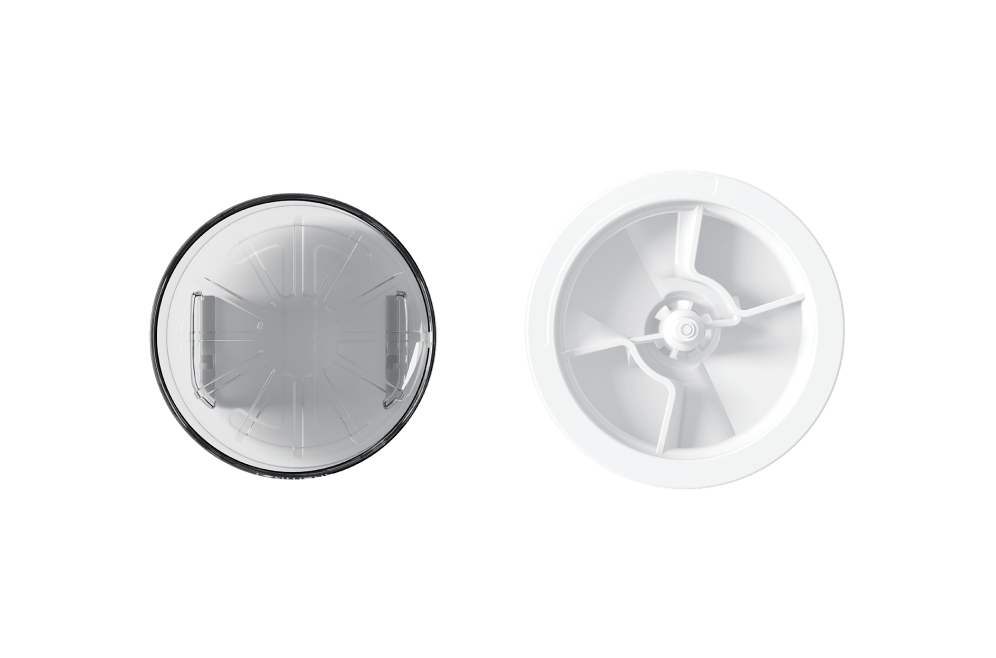

Kneading Kit

Find quick solutions to frequently asked questions.

Still need help?

Reach us at

support@rotimatic.com or Chat with us

What makes Rotimatic NEXT superior to its previous model?

An incredibly sophisticated engineering marvel, the Rotimatic NEXT introduces Vision AI and enhanced Kneading Intelligence to significantly improve the functionality of the Rotimatic. Leading to greater accuracy and consistency in the quality of the dough as well as the thinness and roast quality of the rotis. The Rotimatic NEXT has been designed to handle multiple flours. From the regular wheat flour to gluten-free flours like almond flour, sorghum flour, brown rice flour and more. It allows you to make a wider variety of recipes that include Gluten-free Rotis, parathas, puris, pizzas, millet flatbreads, tortillas and more, with absolute ease. The Rotimatic NEXT is significantly quieter and comes in a sleeker, contemporary design that will be a stunning addition to your kitchen.

Is Rotimatic NEXT quieter than Rotimatic Plus?

Yes, Rotimatic NEXT operates with whisper quiet efficiency. Built-in noise reduction ensures that while an incredibly complex system of motors, sensors and other moving parts work in perfect tandem inside, you barely hear a sound.

Apart from rotis, what other recipes can I make with the Rotimatic NEXT?

Your Rotimatic NEXT is designed to handle multiple flours. From the regular wheat flour to gluten-free flours like almond flour, sorghum flour, brown rice flour and more. This lets you explore and experiment with a wide range of flatbreads. You can make Gluten-free Rotis, parathas, puris, pizzas, millet flatbreads, tortillas and more, with absolute ease.

What are the dimensions and weight of Rotimatic NEXT?

The Rotimatic NEXT measure 28cm (W) x 46.5cm (D) x 37cm (H) (18 x 14 x 11 inches) and weighs 19 kg (42 lbs). Its sleek design makes it a stunning, compact addition for your kitchen.

Is Rotimatic NEXT compatible with my region's voltage?

Yes, Rotimatic NEXT supports:

- 110 - 120V for the USA and Canada

- 220 - 240V for India, UK, Singapore, Australia, Europe, and the Middle East

How do the rotis made by Rotimatic NEXT compare with those made by its previous model?

The Rotimatic NEXT is designed to produce thinner, softer rotis with significantly enhanced consistency and quality, tailored to your taste preferences.

How will I maintain and clean my Rotimatic NEXT?

The Rotimatic NEXT is designed for easy maintenance. The key parts are removable and washable, and the machine will guide you with prompts for cleaning.

What is the warranty coverage for Rotimatic NEXT?

We offer a 1-year Manufacturer's Warranty to cover any issues, along with an optional 3-years Extended Warranty for additional coverage. During the warranty period, any technical or manufacturing issues will be handled at no additional cost to you.

What kind of support is available if I face any issues?

We provide 24x7 customer support to assist you. Our expert technical team offers:

- Remote troubleshooting and debugging

- Live technical assistance

- Step-by-step guidance for resolving any issues

How do I contact customer support if I need help?

Our support team has your back at all times. You can reach us via any of the following ways:

- Live chat on the Rotimatic website or App

- Email support

- 24x7 phone support